Common Materials for Outdoor Furniture: A Popular Science Guide

- Share

- Issue Time

- Jun 9,2024

Summary

Outdoor braided rope materials occupy an important position in furniture and decorations. The characteristics and applicable scenarios of each material are different. Understanding this information will help you make a more appropriate choice and create a long-lasting and beautiful outdoor space.

Common Materials for Outdoor Furniture: A Popular Science Guide

——Acrylic

Acrylic fiber is the trade name of polyacrylonitrile in China, it is called “Orlon” by Dupont of the United States, “Cashmere Nylon” and “Vonnel” in Japan, and “Courtelle” by in England.

It is a kind of synthetic fiber after Polyester (Polyester) and Polyamide (Nylon, Polyamide).

Polyacrylonitrile is obtained from monomer acrylonitrile through the free radical polymerization.

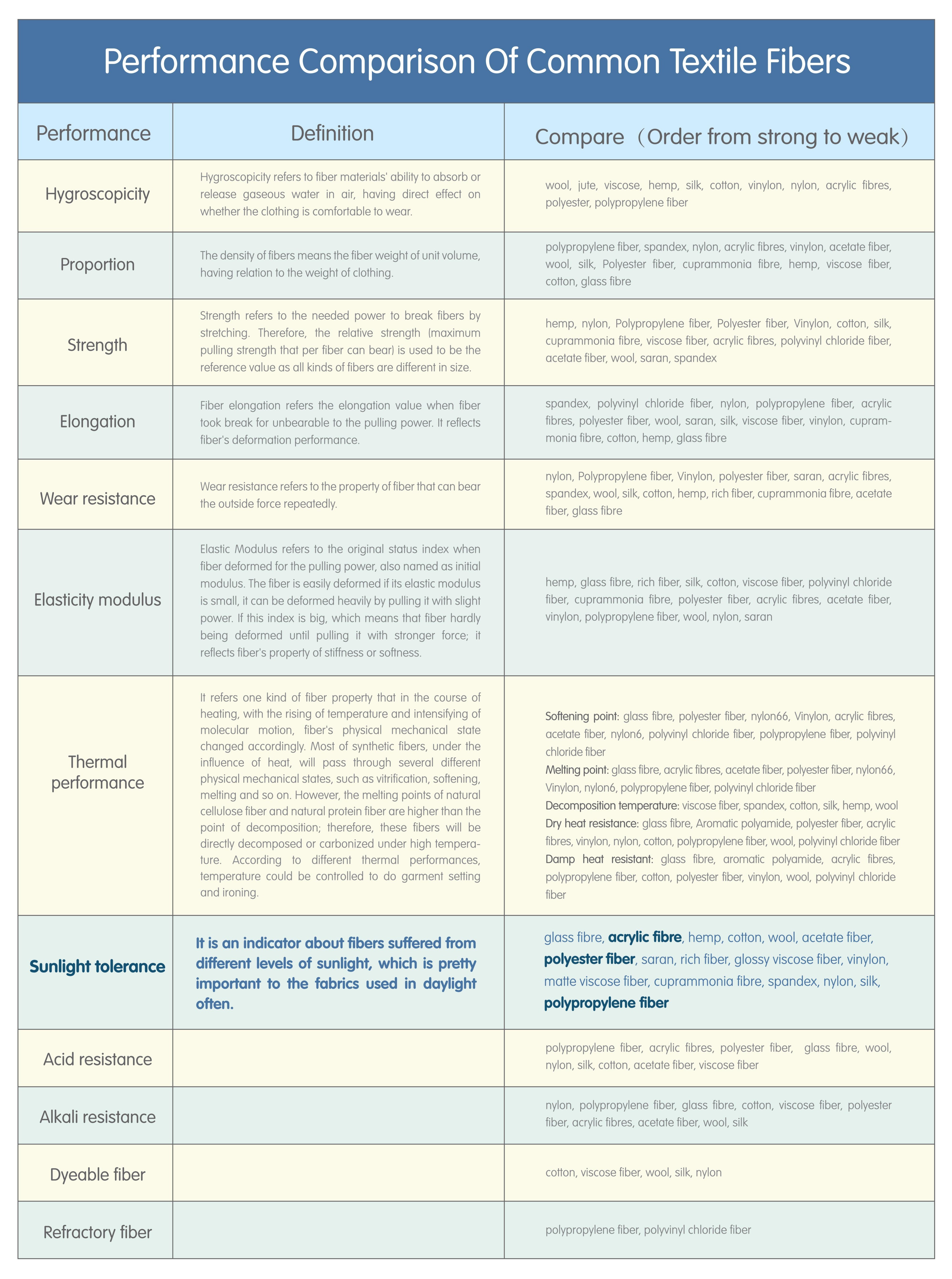

The advantages of acrylic fiber are good weather resistance and high light resistance.

The main characteristics of acrylic fiber:

Light resistance: the light resistance of acrylic fiber is the best among all synthetic fibers. Its strength only decreases by 20% after one year of exposure in the open air. It can maintain 77% of its original strength after being left outdoors for 18 months due to its excellent anti-ultraviolet performance, high and low temperature resistance. Therefore, it is especially suitable for manu- facturing outdoors fabrics such as tents, outdoor furniture fabric, gun covers, car canopies and curtains.

Density: the density of acrylic fiber is generally 1.16 ~ 1.18 g/cm3. Its fiber characteristics are soft, fluffy and good heat reservation. It is a kind of short fiber like wool, which has a lower density than wool and is commonly called artificial wool. Although it is more than 10% lighter than wool, its heat reservation is about 15% higher and its strength is more than 2 timers stronger than wool.

Stain resistance: acrylic fiber has good stain resistance, good weather resistance, mildew proofing and moth proofing. It not only will not mold, but also not be eaten by moth. Acrylic is resistant to acids, oxidants and general organic solvents, but it is not resistant to alkali.

Elastic strength: the elasticity of acrylic fiber good, only after polyester, which is about 2 times higher than that of nylon. It has good shape retention. But it is not as strong as polyester.

Heat resistance: the softening temperature of acrylic fiber is 190 ~230 C, which is second only to polyester in synthetic fiber.

——Polyester

Polyester is the trade name of polyester fiber in China.

Polyester is the world’s largest and most widely used synthetic fiber. It accounts for more than 60% of the world’s synthetic fiber. And it is the simplest one of the three synthetic fiber and the price is relatively cheap.With the characteristics of strong, durable, good elasticity, good light resistance, corrosion resistance, easy washing and quick drying, it is loved by people.

Polyester is also called terylene. Americans call it “dacron”. And it is widely known as “Dacron” in China.

Characteristics

High strength: The strength of short fiber is 2.6~5.7cN/dtex, while the high strength fiber is 5.6 ~ 8.0 cN/dtex. Due to its low hygroscopicity, its wet strength and dry strength are basically same. And its impact strength is 4 times high than nylon and 20 times higher than viscose fiber.

Good light resistance. Its light resistance is second only to acrylic. Polyes- ter fabrics have better light resistance, which is better than natural fiber fabrics and only inferior to acrylic. Especially the light resistance behind glass, it is about the same with acrylic.

Good elasticity:Its elasticity is close to wool’s elasticity. It can be almost completely restored when it is stretched by 5% ~ 6%. And its wrinkle resistance is better tan other fibers, that is, the fabric does not wrinkle easily and has good dimensional stability. The elastic module is 22 ~ 141 cN/dtex, which is 2 ~ 3 times higher than nylon. With its high strength and elastic recov- ery force, it is strong, durable, anti-wrinkle and easy-care.

Corrosion resistance:It is resistant to bleach, oxidants, hydrocarbons, ketones, petroleum products and inorganic acids. It is resistant to dilute alkali and mildew, but it will be resolved in thermokalite. In addition, it has strong resistance to acid, alkali and UV.

Good heat resistance:Polyester is made by melt-spinning. The formed fibers can be heated and melted again, which belongs to thermoplastic fibers. The surface of polyester is smooth and the internal molecules are densely packed, therefore, polyester is the best heat-resistant material in synthetic fabrics. The melting point of polyester is relatively high, so its heat resistance and thermal insulation are higher, which is the best of synthetic fibers.

Good abrasive resistance:Its abrasive resistance is second only to nylon, and better than other natural and synthetic fibers. It is the second one among synthetic fibers.

As clothing fiber, polyester fabric can achieve the effect of no wrinkle and ironing after washing.

It is often blended or interwoven with various fibers, such as cotton polyester, wool polyester, etc., and is widely used in various clothing and decorative materials.Polyester can be used in conveyor belts, tents, canvas, cables, fishing nets, etc., especially the polyester cords for tire, which are close to nylon in performance. Polyester can also be used in electrical insula- tion materials, acid-resistant filter cloths, medical industry cloths and so on.

Categories

Polyester can be divided in short fiber, drawn yarn (low-speed drawn yarn DY, fully drawn yarn FDY, fully oriented yarn FOY), textured yarn (normal textured yarn TY, drawn textured yarn DTY, air textured yarn ATY). decorative filaments, industrial filaments, and various differentiated fibers.

——Olifen

Polypropylene is the trade name of polypropylene fiber.It is made of propylene as raw material by polymerization, melt spinning fiber.

Polypropylene officially began industrial production in 1957, and is a rising star among synthetic fibers.

Because of the advantages of simple production technology, low price, high strength and low relative density, polypropylene has developed rapidly. Polypropylene is currently the fourth largest variety of synthetic fibers.

The main characteristics of polypropylene

Melting point:Polypropylene fiber has a low melting point (165 ~ 173

℃). It is melted at 165℃, softens at about 155℃. the operating temperature range is -30 ~ 140 ℃. it melts near the flame and is flammable. It burns slowly and emits black smoke form fire. The upper end of the flame is yellow, and the lower end is blue. It emits the smell of petroleum, and the ashes after burning are hard, round and light brown particles, which are fragile by hand twisting.

Density:The biggest advantage of polypropylene is light texture. Its density is only 0.91 g/cm3, which is the lightest among common chemical synthetic fibers. It can float on the water due to its lower density than water.

Light resistance: Polypropylene has poor light resistance and thermal stability. It is easy aging and not resistant to ironing. However, anti-aging agent can be added during spinning to improve its anti-aging performance.

Strong elongation: Polypropylene has high strength, large elongation, high initial modulus and excellent elasticity. Therefore, polypropylene has good abrasion resistance. In addition, the wet strength of polypropylene is basically equal to the dry strength, so it is an ideal material for making fishing nets and cables.

Hygroscopicity:Polypropylene has very little hygroscopicity, and the moisture regain in normal atmospheric conditions is close to zero. But it can transfer water vapor through the capillaries in the fabric because of its wicking effect.

Dyeing ability:Polypropylene has poor dyeing ability and incomplete chromatograms. However, its shortcomings can be made up by the method of dope dyeing. All existing polypropylene fibers adopt dope dyeing.

Acid and alkali resistance:Polypropylene has good chemical resistance. Except concentrated nitric acid and strong caustic soda, polypropylene is good at resisting to acids and alkali, so it is suitable for filter materials and packaging materials.

Polypropylene is widely used in the manufacture of industrial fabrics and non-woven fabrics, such as carpets, non-woven fabrics, industrial filter cloths, ropes, fishing nets, cigarette filter tows, building reinforcements, oil-absorbing blankets and decorative cloths.

For civil use, polypropylene can be pure-spun or blended with wool, cotton or viscose to make a variety of clothing. In addition, polypropylene film fiers can be used as packaging materials.

——Nylon

Polyamide fiber commonly named Nylon, English name Polyamide (PA), also known as Chinlon.Nylon is a term for polyamide fiber (poly- amide), used to make long or staple fibers.

Advantages of nylon

High strength and good wear resistance: 1,The biggest advantage of polyamide fiber fabric is strong wear-resisting, wear-resisting property is the first of all kinds of fabrics, it is many times higher than other fiber fabric compared with similar products. It’s higher than cotton 10 times, and higher than wool 20 times, it is the ideal material for making anti-friction products; 2, Light weight and small density-- it is only listed in polypropylene, acrylic fabric in the synthetic fiber fabric for the light weigt, so the weight is lighter than cotton and viscose fiber,Therefore, it’s suitable for making mountaineering clothing, winter clothing, etc; 3, Good elasticity and resistance to fatigue damage--nylon fabric has excellent elasticity and resilience, the degree of styling and retention is second only to polyester; 4, Nylon has better dyeing property than polyester; 5, alkali resistance and resistance to reducing agent action good, not afraid of mold, not afraid of moth.6, low temperature resistant--nylon filament has a good low temperature resistance, the resilience doesn’t change much in the minus 70℃ below.

Disadvantages of nylon

1, The heat resistance is poor,it will become yellow, strength and elongation decreased significantly after 5 hours at 150℃. shrinkage rate increased.Care should be paid to the condition of washing and maintenance in the process of wearing and using nylon fabric to avoid damaging the fabric; 2,Poor light resistance--the biggest disadvan- tage of nylon fabric is poor sun resistance, the fabric will turn yellow for a long time, strength decline, not suitable for outdoor fabric production; 3, Hygroscopicity is low and uncomfortableness, but better than acrylic, polyester; 4, Poor acid resistance, bad resistance to oxidants; 5, Static electicity-It has very low dc conductivity, so easy to produce static electricity due to friction in the process of processing,that clothing wear for long time, easy to hair, pilling; 6, Easy to deform--the initial modulus of nylon is small, it is easy to deform under the external force, so it is easy to wrinkle and not smooth when wearing.

Application of nylon

Filament, used mostly in the knitting and silk industries; Short fiber, mostly mixed with wool or chemical fiber wool, for gabardine, vanidine, etc. Industry: tire cord and fishing nets, also used for carpets, ropes, conveyor belts, screens, etc.

Identification of nylon

The luster of nylon is darker, the surface is like coated with a layer of wax, color is not bright.Feel is stiff, it has the crease and slowly restore the original state when loosen after pinching the fabric.The fastness of warp and weft is great.

The method of washing and protecting for nylon

1, It is not high for the requirements of detergent , the water temperature should not exceed 40 degrees, to avoid the temperature is too hot and out of shape;2, Do not rub vigorously when washing, so as not to appear small hair ball; 3, Should be washed several more times for the light color fabric, otherwise easy to become yellow; 4, Don’t expose to the sun and drying, should be drying in the shade; 5, Due to the heat resistance is poor, so should iron with low tempera- ture, must play steam, not dry hot.