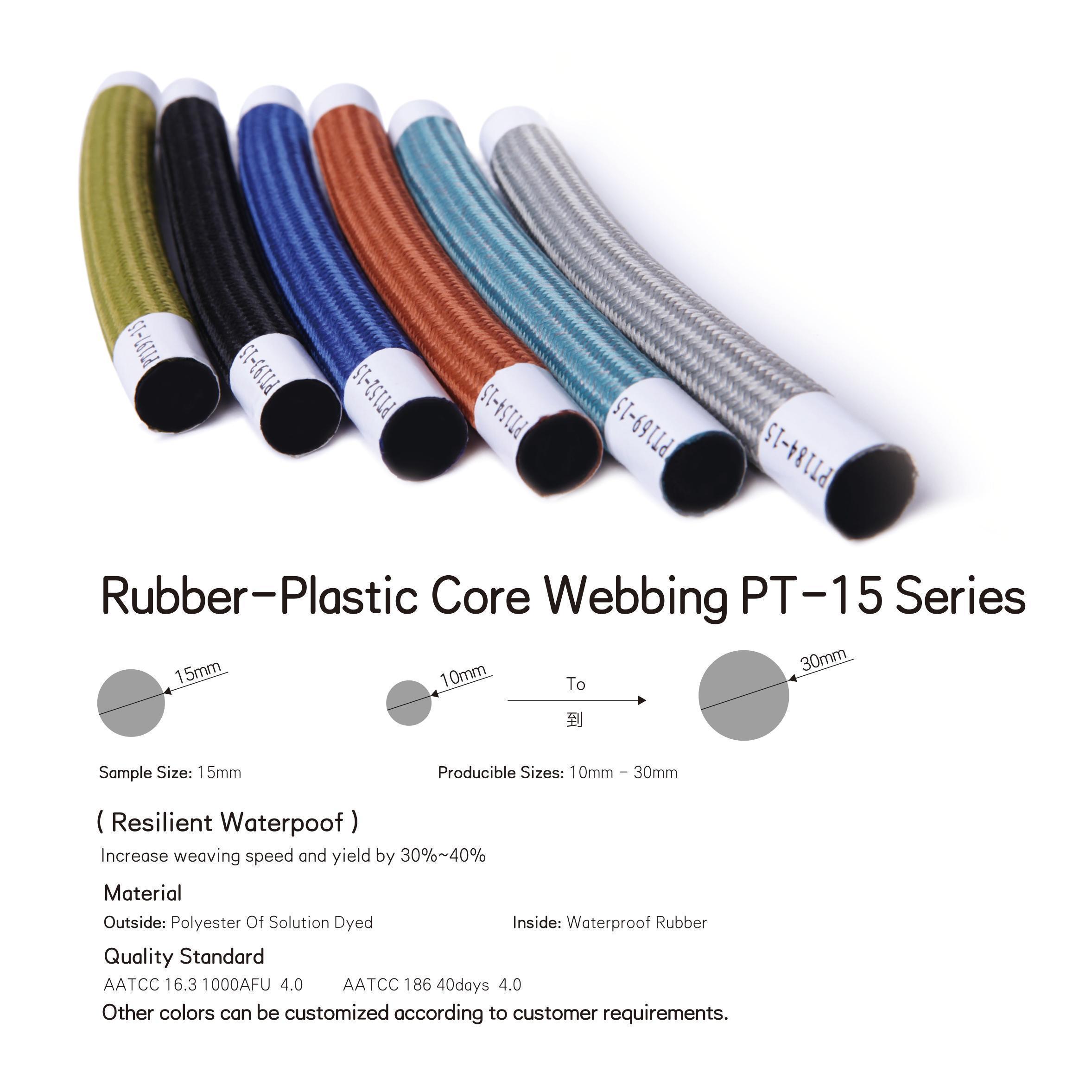

Wholesale Olefin Rubber Core Webbing PT-15 Series | Suitable for Outdoor Furniture | Waterproof and Quick Drying | Raw Material Supplier

- Model

- Olefin Rubber-Plastic Core Webbing PT-15 Series

Item specifics

- Material Outside

- Solution Dyed Olefin

- Material Inside

- Waterproof Rubber

Review

Description

Olefin Rubber-Plastic Core Webbing PT-15 Series Material Introduction

The Olefin Rubber-Plastic Core Webbing PT-15 series material is a braided rope material designed for high-end outdoor furniture. The outer layer is made of high-quality polyolefin fiber, which is known for its excellent UV resistance and weather resistance, and the inner layer is made of waterproof rubber core. Through advanced production technology, it is woven into a neutral extensibility structure, which makes it smoother during the weaving process. At the same time, it has strong wear resistance and can resist the loss caused by frequent use and friction. This series of materials is not only light and easy to handle, but also has good breathability and quick drying performance. It is very suitable for various outdoor environments. The product also provides a variety of colors for designers to choose.

Olefin Rubber-Plastic Core Webbing PT-15 Series Material Specification

Our material products are round rope products developed and designed based on the issues encountered during long-term use of outdoor furniture products. They feature excellent mold resistance, water resistance, quick drying, high UV resistance, high color fastness, flame retardancy, and sustainability. Our round rope materials come in a variety of colors for selection.

Olefin Rubber-Plastic Core Webbing PT-15 Series Olefin Material Parameter

|

Material: |

Olefin of solution dyed

|

||

|

Sample Size : |

D 15mm

|

||

Producible Size : | D 10mm-30mm | ||

|

Function: |

Resistance, Water Resistance, Quick Drying, High UV Resistance, High color Fastness, Flame Retardancy, GLS

|

||

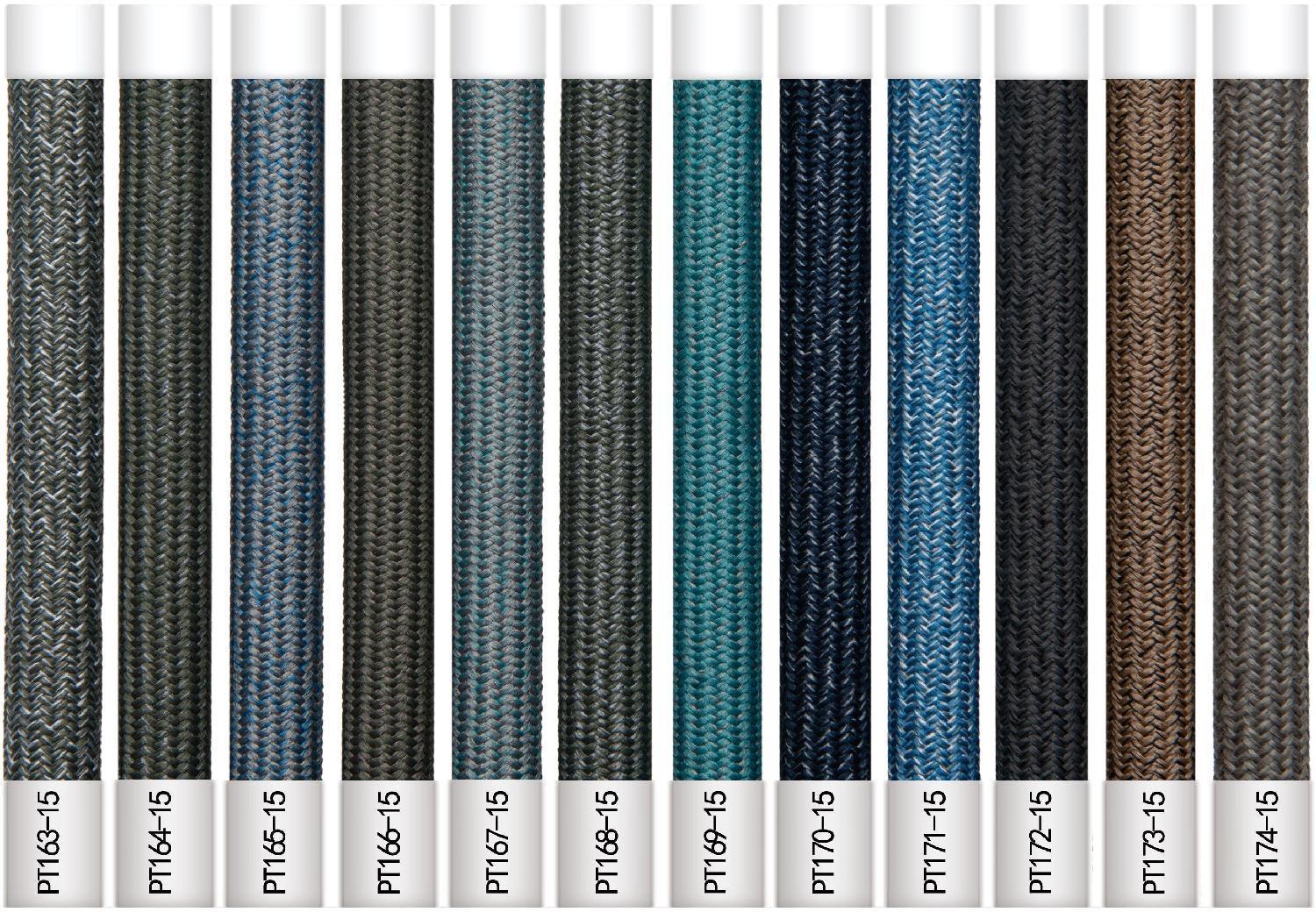

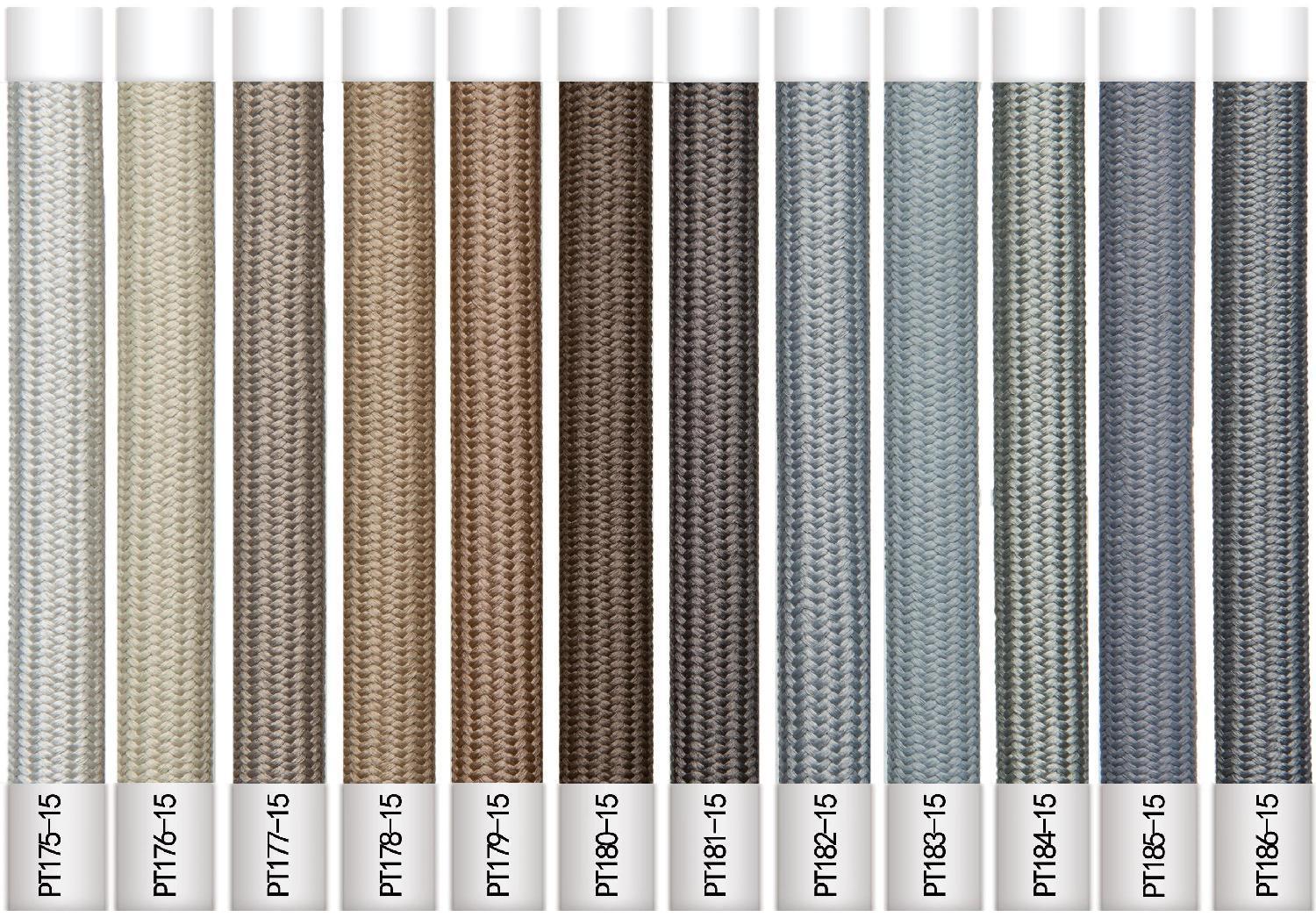

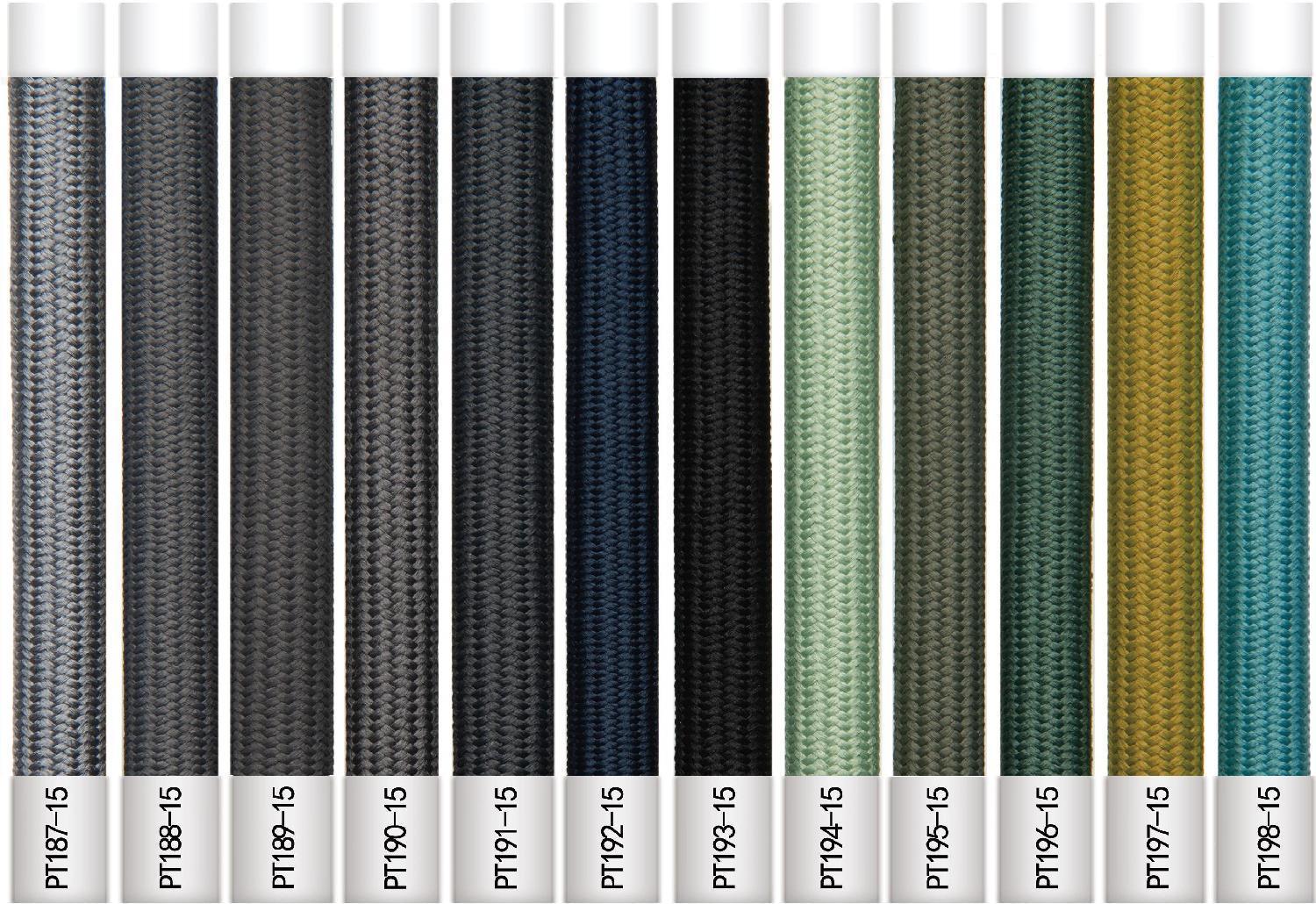

Olefin Rubber-Plastic Core Webbing PT-15 Series Olefin Available color

Click On The Picture Below To Customize Your Own Braided Rope

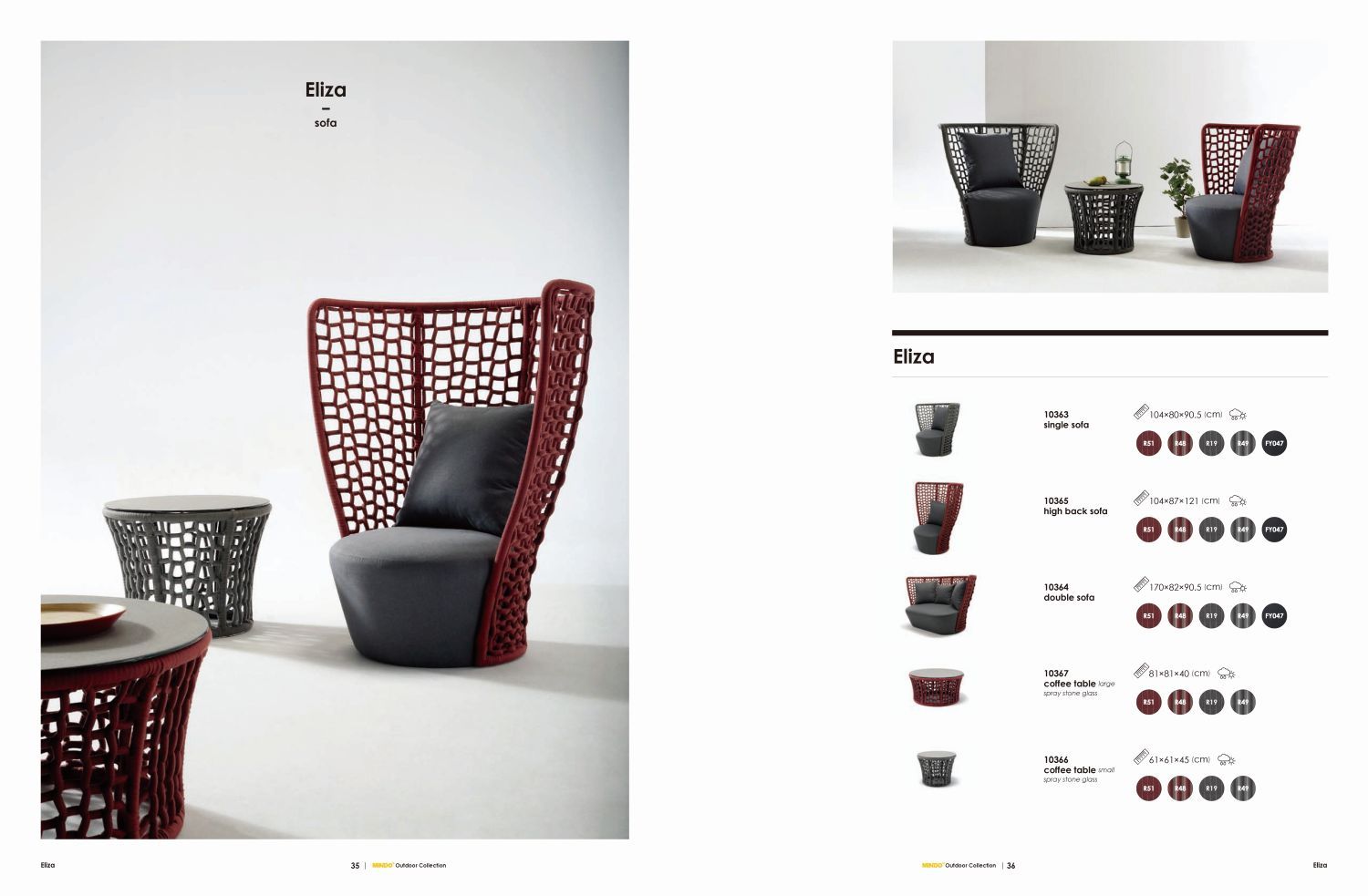

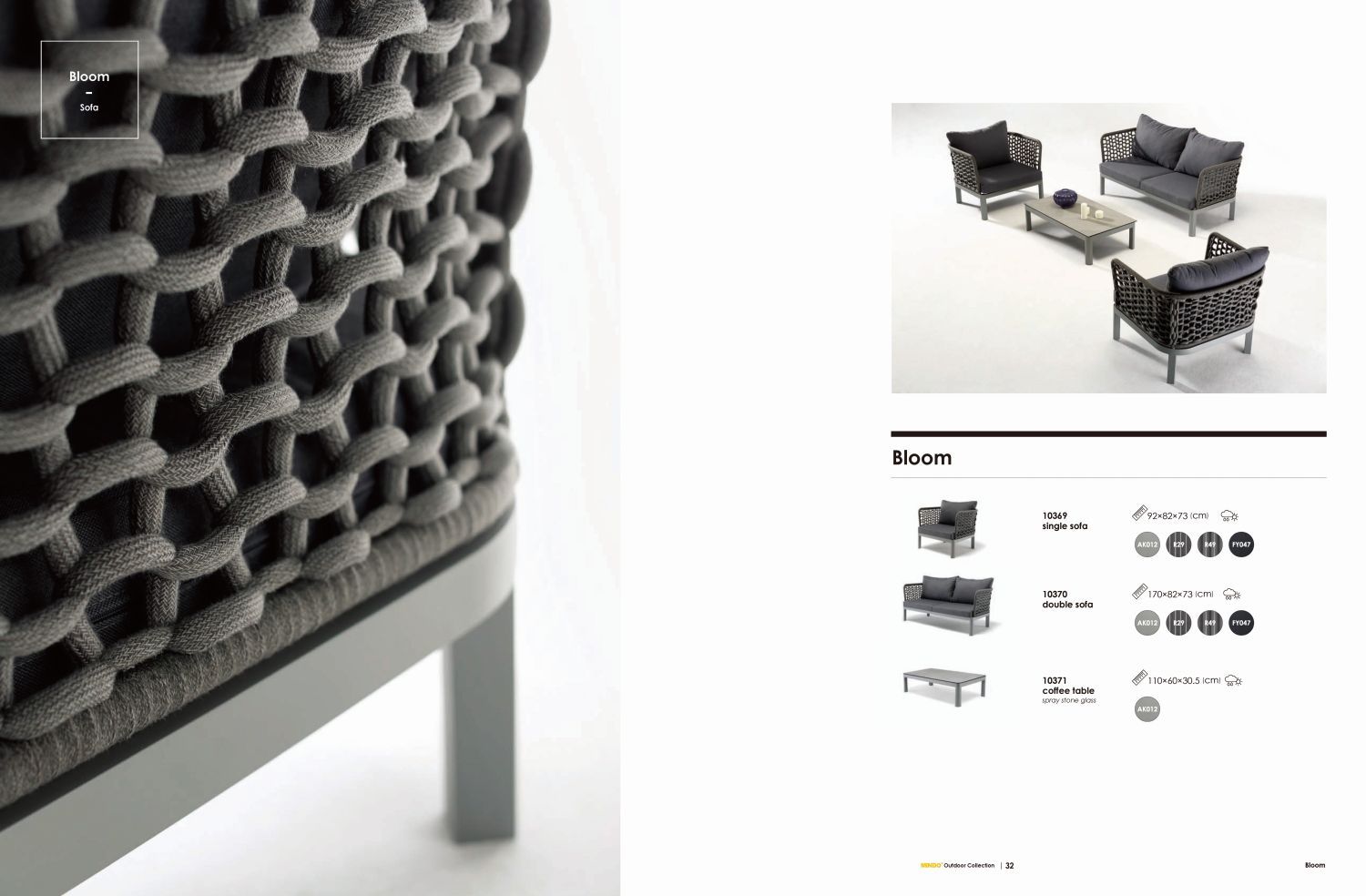

Olefin Rubber-Plastic Core Webbing PT-15 Series Case Studies of Collaborative Clients

Performance Comparison Of Common Textile Fibers | ||

|

Performance

|

Definition

|

Compare (Order from strong to weak)

|

|

Hygroscopicity

|

Hygroscopicity refers to fiber materials' ability to absorb orrelease gaseous water in air, having direct effect onwhether the clothing is comfortable to wear.

|

wool, jute, viscose, hemp, silk, cotton, vinylon, nylon, acrylic fibres,polyester, polypropylene fiber

|

|

Proportion

|

The density of fibers means the fiber weight of unit volume,having relation to the weight of clothing.

|

polypropylene fiber, spandex, nylon, acrylic fibres, vinylon, acetate fiberwool, silk, Polyester fiber, cuprammonia fibre, hemp, viscose fibercotton, glass fibre

|

|

Strength

|

Strength refers to the needed power to break fibers bystretching. Therefore, the relative strength (maximumpulling strength that per fiber can bear) is used to be thereference value as all kinds of fibers are different in size.

|

hemp, nylon, Polypropylene fiber, Polyester fiber, Vinylon, cotton, silkcuprammonia fibre, viscose fiber, acrylic fibres, polyvinyl chloride fiberacetate fiber, wool, saran,spandex

|

Elongation | Fiber elongation refers the elongation value when fibeltook break for unbearable to the pulling power. it reflectsfiber's deformation performance. | spandex, polyvinyl chloride fiber, nylon, polypropylene fiber, acrylifibres, polyester fiber, wool, saran, silk, viscose fiber, vinylon, cupram.monia fibre, cotton, hemp, glass fibre |

Wear resistance | Wear resistance refers to the property of fiber that can bearthe outside force repeatedly. | nylon, Polypropylene fiber, Vinylon, polyester fiber, saran, acrylic fibresspandex, wool, silk, cotton, hemp, rich fiber, cuprammonia fibre, acetatefiber, glass fibre |

Elasticity modulus | Elastic Modulus refers to the original status index whenfiber deformed for the pulling power, also named as initia!modulus. The fiber is easily deformed if its elastic modulusis small, it can be deformed heavily by pulling it with slightpower. lf this index is big, which means that fiber hardlybeing deformed until pulling it with stronger force: itreflects fiber's property of stiffness or softness. | hemp, glass fibre, rich fiber, silk, cotton, viscose fiber, polyvinyl chloridefiber, cuprammonia fibre, polyester fiber, acrylic fibres, acetate fibervinylon, polypropylene fiber, wool, nylon, saran |

Sunlight tolerance | It is an indicator about fibers suffered fromdifferent levels of sunlight, which is prettyimportant to the fabrics used in daylighoften. | glass fibre, acrylic fibre, hemp, cotton, wool, acetate fiber,polyester fiber, saran, rich fiber, glossy viscose fiber, vinylonmatte viscose fiber, cuprammonia fibre, spandex, nylon, silk.polypropylene fiber |

What is solution coloring

The solution dyeing method is to add appropriate colorants to the spinning solution, fully mix, dissolve and filter, or quantitatively inject colorants or colored stock solution before entering the spinneret, and then mix in a static mixer to spin into colored fibers. Quanshun's colored polyester yarn, acrylic yarn, polypropylene yarn and other yarns are all made by the solution dyeing process. All the company's pigments are imported color powders from BASF in Germany and Klein in the United States.

Advantages of solution coloring

Uniform coloring: Due to the accurate control of the color content of the dye, the liquid dye can ensure uniform dyeing of the items. Generally, the darker the color, the higher the color fastness, which is the opposite of dyeing.

Bright color: The liquid dye has bright and long-lasting color and is not easy to fade.

Economical and practical: The liquid dye is economical and practical, easy to handle and transport.

Environmental protection: Processing each ton of liquid-dyed fiber into textiles can reduce wastewater discharge by 32 tons, reduce carbon dioxide emissions by 1.2 tons, reduce power consumption by 230 kilowatts, and reduce steam consumption by 3.5 cubic meters.

Home Weaving Method

Own warehouses, workshops and testing rooms to ensure high quality of customized braided ropes